This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Atomic-scale semiconductor process technology and clean hydrogen technology join hands

Solid oxide fuel cells (SOFC) are widely used for energy storage, transportation, and various applications, employing solid electrolytes such as ceramics. The efficiency of these cells relies on the performance and stability of their electrodes.

To enhance this efficiency, there is a requirement to fabricate electrodes with a porous structure. Unfortunately, existing technologies face challenges in achieving a uniform coating of ceramic materials within electrodes possessing intricate porous structures.

A collaborative research team, comprising Professor Jihwan An and Ph.D. candidate Sung Eun Jo from the Department of Mechanical Engineering at Pohang University of Science and Technology (POSTECH), and others, has successfully produced porous electrodes for SOFCs using latest semiconductor processes. This research has been featured as a back cover article in Small Methods.

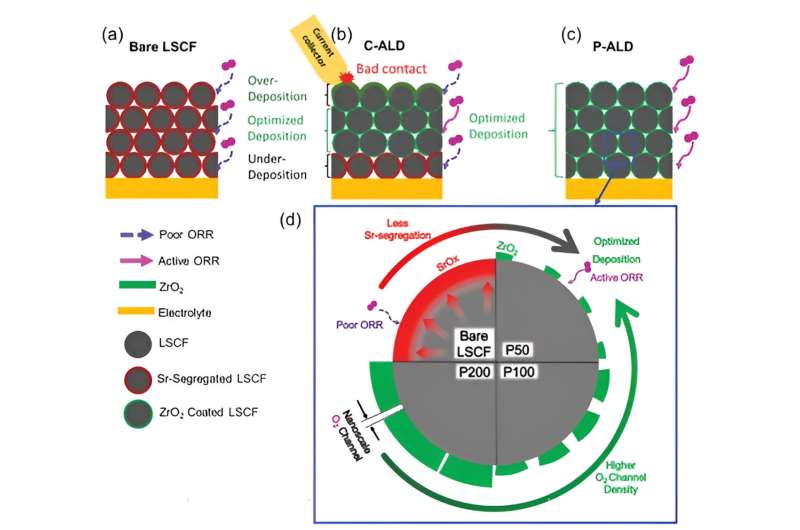

The process of atomic layer deposition (ALD) involves depositing gaseous materials onto a substrate surface in thin, uniform atomic layers. In a recent study, Professor Jihwan An's team, known for their prior work in enhancing the efficiency of SOFCs using ALD, developed and applied a powder ALD process and equipment. This enabled them to precisely coat nano-thin films on fine powders.

The team used this process to uniformly coat a zirconium oxide (ZrO2) ceramic material onto a porous structured cathode (LSCF). Unlike traditional ALD processes for semiconductors that primarily adsorb gaseous reactants onto the surface of porous structures and face limitations in penetrating complex pores, the team employed an atomic layer process on powdered electrode materials and successfully deposited these materials inside the structure.

In experimental trials, the team's electrodes demonstrated a remarkable 2.2-fold increase in the maximum power density of the cells compared to conventional ones, even in high-temperature environments (700–750°C). Furthermore, they achieved a 60% reduction in activation resistance, a factor that typically diminishes cell efficiency.

In response to this issue, the research team have developed an innovative prosthetic hand tailored for a patient who lost their thumb and index finger in a car accident. This advanced prosthesis operates by interpreting signals from the brain to the muscles through sensors. Unlike conventional prosthetics, it incorporates a wrist rotation module, enabling patients to enjoy unrestricted movement of their wrists.

Professor Jihwan An who led the research said, "This signifies a breakthrough in green energy systems through the application of advanced semiconductor process-based technology. Powder ALD technology holds immense potential in various applications including SOFCs, hydrogen production, and secondary battery devices such as SOECs."

He added, "We will continue our research endeavors to enhance sustainable solutions for green energy."

More information: Sung Eun Jo et al, Simultaneous Performance and Stability Enhancement in Intermediate Temperature Solid Oxide Fuel Cells by Powder‐Atomic Layer Deposited LSCF@ZrO2 Cathodes, Small Methods (2023). DOI: 10.1002/smtd.202300790

Journal information: Small Methods

Provided by Pohang University of Science and Technology